lifetime shed instructions pdf

Welcome to the Lifetime Shed Instructions PDF, your comprehensive guide to assembling and maintaining your shed. This manual provides step-by-step instructions, pre-assembly preparation tips, and key features to ensure a successful and enjoyable experience. Follow these detailed guidelines to build your shed with confidence and precision.

Overview of Lifetime Shed Products

Lifetime sheds are renowned for their durability and sleek designs, offering high-quality outdoor storage solutions. Constructed with weather-resistant materials, these sheds provide ample space for gardening tools, equipment, and more. Available in various sizes and styles, Lifetime sheds cater to diverse needs, ensuring functionality and aesthetics. Their sturdy build and modern designs make them a popular choice for homeowners seeking reliable storage options. Customers praise their resilience and spacious interiors.

Importance of Following Assembly Instructions

Following the Lifetime Shed Instructions PDF is crucial for a successful assembly. Properly assembled sheds ensure safety, stability, and optimal performance. Deviating from instructions can lead to structural issues or safety hazards. The manual provides precise steps to avoid errors and ensure all components fit correctly. By adhering to the guide, you’ll achieve a durable, weather-tight shed that meets manufacturer standards. Ignoring instructions may void warranties or compromise the shed’s integrity. Always read and follow the manual carefully to guarantee a flawless assembly process.

Pre-Assembly Preparation

Pre-assembly preparation involves gathering all tools, materials, and ensuring the site is level and clear. Organize parts and hardware to streamline the assembly process effectively.

Tools and Materials Required

Ensure you have all necessary tools and materials before starting. Common tools include screwdrivers, wrenches, and a rubber mallet. Check the instruction manual for specific hardware requirements. Gather all parts, bolts, and fasteners provided. Verify the completeness of the kit to avoid delays. Organize items for easy access during assembly. Proper preparation ensures a smooth and efficient process.

Choosing the Right Location for Your Shed

Select a flat, dry area for your shed to ensure proper drainage and stability. Avoid low-lying spots prone to water pooling. Consider sunlight exposure and wind direction for optimal placement. Clear the site of debris and vegetation. Ensure the location complies with local building codes and regulations. Proper site preparation ensures a stable foundation and prolongs the shed’s lifespan. Plan carefully to maximize functionality and aesthetic appeal.

Understanding the Assembly Process

Understanding the assembly process involves following detailed steps, identifying parts, and ensuring proper alignment. This section provides a clear overview to help you prepare and execute the assembly efficiently.

Step-by-Step Guide to Shed Assembly

Begin by gathering all tools and parts. Start with the base, ensuring it’s level and secure. Follow the manual to assemble panels, attaching them to the base. Install the roof, aligning it carefully. Double-check all connections and hardware. Refer to diagrams for clarity. If unsure, consult online resources or customer support. Complete with final inspections to ensure structural integrity and durability.

Common Mistakes to Avoid During Assembly

Avoid misidentifying parts, as this can delay assembly. Ensure the base is level to prevent structural issues. Tighten hardware gradually to maintain alignment. Don’t skip steps, as this may lead to instability. Verify all panels are securely attached before moving on. Misaligned roof sections can compromise integrity, so double-check placements. Following instructions carefully minimizes errors and ensures a sturdy, long-lasting shed. Proper preparation is key to a successful assembly process.

Key Features of Lifetime Sheds

Lifetime sheds are known for their durable, weather-resistant materials, spacious designs, and stylish options, offering long-lasting performance and versatility for various storage and organizational needs.

Durable and Weather-Resistant Materials

Lifetime sheds are crafted with high-quality, weather-resistant materials, such as durable steel frames and UV-protected polyethylene, ensuring long-lasting performance. These materials withstand harsh weather conditions, including heavy rain, strong winds, and intense sunlight. The rust-resistant steel and fade-resistant plastic ensure your shed remains structurally sound and visually appealing for years. This construction minimizes maintenance needs and guarantees reliability, making Lifetime sheds a practical and durable storage solution for any outdoor space.

Spacious and Versatile Design Options

Lifetime sheds offer a variety of sizes and styles to meet diverse storage needs. With adjustable shelving and customizable interiors, these sheds maximize space efficiency. Their versatile design allows for tailored solutions, accommodating gardening tools, seasonal decorations, or even workshop areas. The spacious interiors ensure ample room for organization, making them ideal for both residential and commercial use. This adaptability ensures your shed fits seamlessly into your lifestyle and property layout.

Tips for a Successful Assembly

Follow the Lifetime Shed Instructions PDF carefully to ensure a smooth assembly. Organize all parts and tools beforehand. Double-check each step to avoid mistakes, ensuring a sturdy and efficient build.

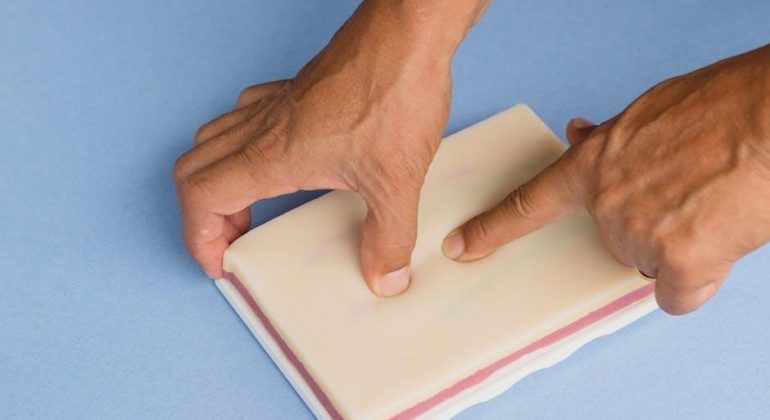

Organizing Parts Before Starting

Organizing parts before starting ensures a smooth assembly process. Begin by unpacking and categorizing components according to the Lifetime Shed Instructions PDF. Use the provided hardware list to verify all items are included. Label and group similar parts together to avoid confusion. This systematic approach saves time, reduces stress, and helps you follow the manual more effectively, ensuring every piece is accounted for and easily accessible when needed.

Using Online Resources for Additional Guidance

Supplement your Lifetime Shed Instructions PDF with online resources for added clarity. Visit Lifetime’s official website for video tutorials and assembly tips. Forums and customer reviews often provide troubleshooting solutions and real-user insights. Additionally, YouTube tutorials and manufacturer FAQs can address specific challenges. These resources complement the manual, offering visual guidance and practical advice to ensure a successful assembly experience, especially for first-time builders.

Troubleshooting Common Issues

Troubleshoot common assembly issues by identifying damaged parts, addressing alignment problems, and ensuring proper fitment. Refer to the manual or contact Lifetime customer support for assistance.

Identifying and Replacing Damaged Parts

Inspect all parts before assembly to identify any damage. Use the manual to match parts with their descriptions. If damaged, contact Lifetime customer service for replacements. Ensure proper tools are available for disassembly and reassembly. Organize parts carefully to avoid confusion. Replacing damaged components promptly ensures structural integrity and prevents further issues during assembly. Follow the manual’s guidelines for replacement procedures to maintain your shed’s durability and safety.

Addressing Alignment and Fitment Problems

If parts do not align properly, double-check the hardware and instructions. Ensure the foundation is level and secure. Use shims or adjust the base if necessary. Verify all pieces are correctly oriented and fastened. If issues persist, consult the manual or contact customer support for guidance. Proper alignment is crucial for structural integrity and functionality, so address any fitment concerns early to avoid complications during assembly or use.

Maintenance and Care

Regularly clean your shed to prevent dirt buildup. Inspect for damage and perform touch-ups as needed. Ensure longevity by addressing wear promptly and maintaining a dry interior.

Cleaning and Protecting Your Shed

Regular cleaning is essential to maintain your shed’s appearance and durability. Use mild detergents and water to wash the exterior, avoiding abrasive materials that may scratch surfaces. For tougher stains, apply a gentle bleach solution. Rinse thoroughly to prevent residue buildup. Protect your shed by applying weather-resistant sealants yearly, ensuring it withstands harsh weather conditions effectively.

Regular Inspections for Longevity

Performing regular inspections ensures your shed remains in excellent condition. Check for signs of wear, such as rust, rot, or loose hardware. Tighten any bolts or screws and replace damaged parts promptly. Inspect the roof for leaks and the foundation for stability. Addressing issues early prevents costly repairs and extends the lifespan of your shed, ensuring it continues to serve its purpose effectively for years to come.

Customer Support and Resources

Lifetime offers dedicated customer support to assist with assembly questions and issues. Access additional manuals, troubleshooting guides, and contact information for a seamless experience.

Contacting Lifetime Customer Service

Lifetime’s customer service team is available to assist with any questions or concerns. Reach them via phone, email, or live chat for prompt support. Whether you need help with assembly, troubleshooting, or replacing parts, their experts are ready to guide you. For efficient service, have your shed model number and order details handy. Visit their official website for contact information and additional resources to ensure a smooth experience with your shed.

Accessing Additional Assembly Manuals

Lifetime offers convenient access to additional assembly manuals on their official website. Visit www.lifetime.com to download PDF versions tailored to your shed model. For models like the 8×8 or 10×8 sheds, these manuals provide detailed diagrams and step-by-step instructions. If you need a specific guide, contact customer service with your shed’s model number for assistance. This ensures you have all the resources needed for a smooth assembly process.

Customer Reviews and Feedback

Customers praise Lifetime sheds for their durability and ease of assembly. Many highlight the sturdy construction and stylish designs, making them a top choice for storage needs. Reviews often mention excellent build quality and appearance, ensuring satisfaction for years. Positive feedback underscores the value and reliability of Lifetime sheds, encouraging others to choose them for their storage solutions.

Positive Experiences with Lifetime Sheds

Customers often highlight their positive experiences with Lifetime sheds, praising their durability and weather-resistant materials. Many appreciate the spacious and versatile designs, which provide ample storage solutions. Reviews frequently mention the ease of assembly and the high-quality construction that withstands harsh weather conditions. Users also commend the stylish appearance and long-lasting performance, making Lifetime sheds a top choice for outdoor storage needs and enhancing their overall satisfaction with the product.

Lessons Learned from Customer Assembly Stories

Customers often emphasize the importance of organization and preparation when assembling Lifetime sheds. Many highlight the value of carefully following the instructions and avoiding deviations, which can lead to delays. Several users recommend using online resources for additional guidance, while others stress the importance of teamwork for smoother assembly. These shared experiences underscore the need to double-check parts and hardware before starting, ensuring a trouble-free process and a satisfactory outcome with Lifetime sheds.

Comparing Lifetime Sheds to Other Brands

Lifetime sheds are known for their durability and weather-resistant materials, offering a spacious and versatile design. They often outperform other brands in terms of quality and value.

Quality and Durability Comparison

Lifetime sheds excel in quality and durability, featuring robust materials like high-density polyethylene and steel frames, ensuring long-lasting performance. Their weather-resistant design withstands harsh conditions, unlike many competitors. Customers praise the sturdy construction, which maintains structural integrity even in high winds. While other brands may offer lower prices, Lifetime sheds provide superior durability, making them a worthwhile investment for reliable outdoor storage solutions.

Price and Value Analysis

Lifetime sheds offer a balance between quality and affordability, with prices slightly higher than some competitors but justified by their durability. While initial costs may seem steep, their long-lasting materials and low maintenance requirements provide excellent value. Customers often report that the investment pays off over time, as the sheds withstand harsh conditions better than cheaper alternatives. This makes Lifetime sheds a cost-effective choice for those seeking reliable, long-term storage solutions.

Safety Considerations

Ensure a safe assembly process by wearing protective gear, using tools properly, and following instructions to avoid accidents and ensure structural stability and longevity of your shed.

Safe Assembly Practices

Always wear safety goggles and gloves during assembly to protect against debris and sharp edges. Ensure the work area is clear of clutter and tripping hazards. Use tools as intended and avoid over-tightening hardware, which can strip screws or damage parts. Follow the manual’s guidance on lifting techniques to prevent injury and maintain structural integrity. Keep children and pets away from the assembly area. Properly secure loose components to avoid accidents and ensure stability.

Ensuring Structural Integrity

Ensure the shed’s foundation is level and secure to prevent instability. Anchor the shed to the ground using recommended hardware to withstand weather conditions. Verify all panels and frames are properly aligned and securely fastened. Double-check tightness of bolts and screws without over-tightening. Inspect for any damaged or missing parts before assembly. Regular inspections and timely repairs will maintain the shed’s structural integrity and extend its lifespan. Follow manufacturer guidelines for optimal results.

Organizing Your Shed

Maximize your shed’s storage potential with strategic organization. Use shelves, hooks, and bins to keep items accessible and tidy. Label storage containers for easy identification and efficiency.

Maximizing Storage Space

Optimize your shed’s storage capacity by utilizing vertical space with shelves and hooks. Store seasonal items in labeled bins for easy access. Install pegboards for tools and accessories. Consider custom shelving solutions to fit specific needs. Measure items before placing them to ensure efficient use of space. This organized approach will help maintain a clutter-free environment and make the most of your shed’s interior.

Customizing Your Shed for Specific Needs

Easily tailor your Lifetime Shed to meet your unique requirements. Add shelves for tools, cabinets for chemicals, or hooks for bikes and equipment. Incorporate pegboards for hanging items and storage bins for smaller accessories. Customize the layout to maximize functionality, ensuring everything has its place. This personalization allows your shed to serve as a practical workspace or storage solution, perfectly adapted to your lifestyle and preferences.

Environmental Considerations

Lifetime Sheds are designed with eco-friendly materials to minimize environmental impact. Proper disposal of packaging and sustainable practices ensure responsible construction and long-term durability for outdoor use.

Eco-Friendly Material Options

Lifetime Sheds are constructed with durable, weather-resistant materials that minimize environmental impact. Many models feature recyclable components and sustainable manufacturing processes. The sheds are designed to withstand harsh weather conditions while maintaining structural integrity and aesthetic appeal. By choosing eco-friendly options, you support environmental responsibility without compromising on quality or functionality. Proper disposal of packaging materials is also encouraged to further reduce ecological footprint and promote sustainability.

Proper Disposal of Packaging Materials

Proper disposal of packaging materials is essential for minimizing environmental impact. Recycle cardboard, plastic, and metal components whenever possible. Check local recycling guidelines to ensure compliance. Avoid littering or improper disposal of hazardous materials. Lifetime Sheds encourages responsible waste management to promote sustainability and reduce ecological footprint. By following these practices, you contribute to a cleaner and greener environment while maintaining the quality of your shed assembly experience.

Congratulations on completing your Lifetime Shed assembly! This guide has provided essential steps, tips, and best practices to ensure your shed is built to last. Enjoy your new shed and the additional space it provides!

Final Thoughts on Lifetime Shed Assembly

The Lifetime Shed Instructions PDF provides a comprehensive guide for assembling your shed, ensuring a smooth and successful process. With detailed steps, essential tips, and customer-reviewed insights, this manual helps you achieve professional-grade results. Its focus on durability, weather resistance, and ease of assembly makes it a valuable resource for both beginners and experienced DIYers. Start your project with confidence and enjoy your new shed for years to come!

Encouragement to Start Your Project

With the Lifetime Shed Instructions PDF as your guide, you’re empowered to create a durable, weather-resistant storage solution. Don’t hesitate—start your project today! The clear, step-by-step instructions will give you the confidence to build a shed that will last for years. Gather your tools, organize your parts, and take the first step toward enjoying the extra space and satisfaction of a job well done. Your new shed awaits!